How to Check Water Pumps in Hydronic Heating Systems: A Professional Guide by LOCKHOOT

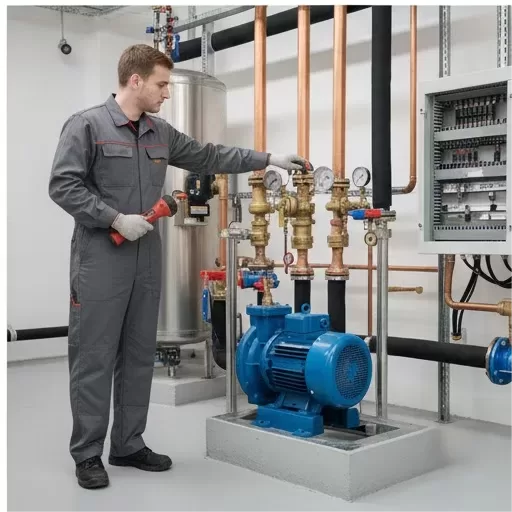

In a hydronic heating system, the water pump (circulator) is the “heart” of the operation. If the pump fails, the entire heating distribution collapses. Regular maintenance and diagnostic checks are essential to ensure system longevity and energy efficiency.

Below is the professional inspection protocol recommended by LOCKHOOT for hydronic water pumps.

1. Visual Inspection & Physical Integrity

Before diving into technical testing, perform a thorough visual assessment:

-

Leakage Check: Inspect the mechanical seals and flange gaskets. At LOCKHOOT, we emphasize that even minor calcification around the pump housing can indicate a slow leak that leads to system pressure loss.

-

Corrosion Assessment: Look for rust on the pump body. While LOCKHOOT pumps utilize high-grade anti-corrosive coatings, external moisture or oxygen ingress in the system can still cause oxidation.

2. Operational Sound and Vibration Analysis

A healthy hydronic pump should operate with a consistent, low-decibel hum.

-

Cavitation Noise: If you hear a sound like “marbles rattling,” the pump is likely experiencing cavitation. This is often caused by low suction pressure or air trapped in the system.

-

Bearing Wear: A high-pitched screeching usually indicates bearing failure. LOCKHOOT’s advanced shielded motor designs minimize this risk, but long-term wear is inevitable in systems with poor water qualit

3. Electrical and Motor Performance Testing

Using a multimeter, verify that the motor is operating within its rated specifications:

-

Voltage Verification: Ensure the power supply matches the pump’s nameplate (e.g., 115V or 230V).

-

Amperage Draw: Measure the running amps. If the pump is drawing significantly more current than the rated FLA (Full Load Amps), the impeller may be jammed, or the motor windings may be failing.

-

Capacitor Check: For single-phase pumps, a faulty start capacitor is a common cause of “fail-to-start” issues.

4. Hydraulic Performance & Differential Pressure

The ultimate test of a pump is its ability to move water against system resistance.

-

Differential Pressure : Measure the pressure at the suction side and the discharge side. The difference tells you exactly where the pump is operating on its performance curve.

-

Flow Confirmation: Ensure that the zones are receiving adequate flow. If the pump is spinning but the pipes remain cold, check for a sheared impeller shaft or a vapor lock.

Why Choose LOCKHOOT for Your Hydronic Projects?

As a specialist in high-efficiency fluid technology, LOCKHOOT understands that downtime is not an option for HVAC professionals. In the U.S. market, where labor costs for repairs are high, installing a reliable LOCKHOOT pump reduces long-term TCO (Total Cost of Ownership).

Need Technical Support or Bulk Inquiries?

If your inspection reveals a failing unit, replace it with a high-performance LOCKHOOT circulator.

[Contact LOCKHOOT Engineering Today for a Consultation]